What our customers have to say about working with Project Engineering

Project process

A practical example of system optimisation

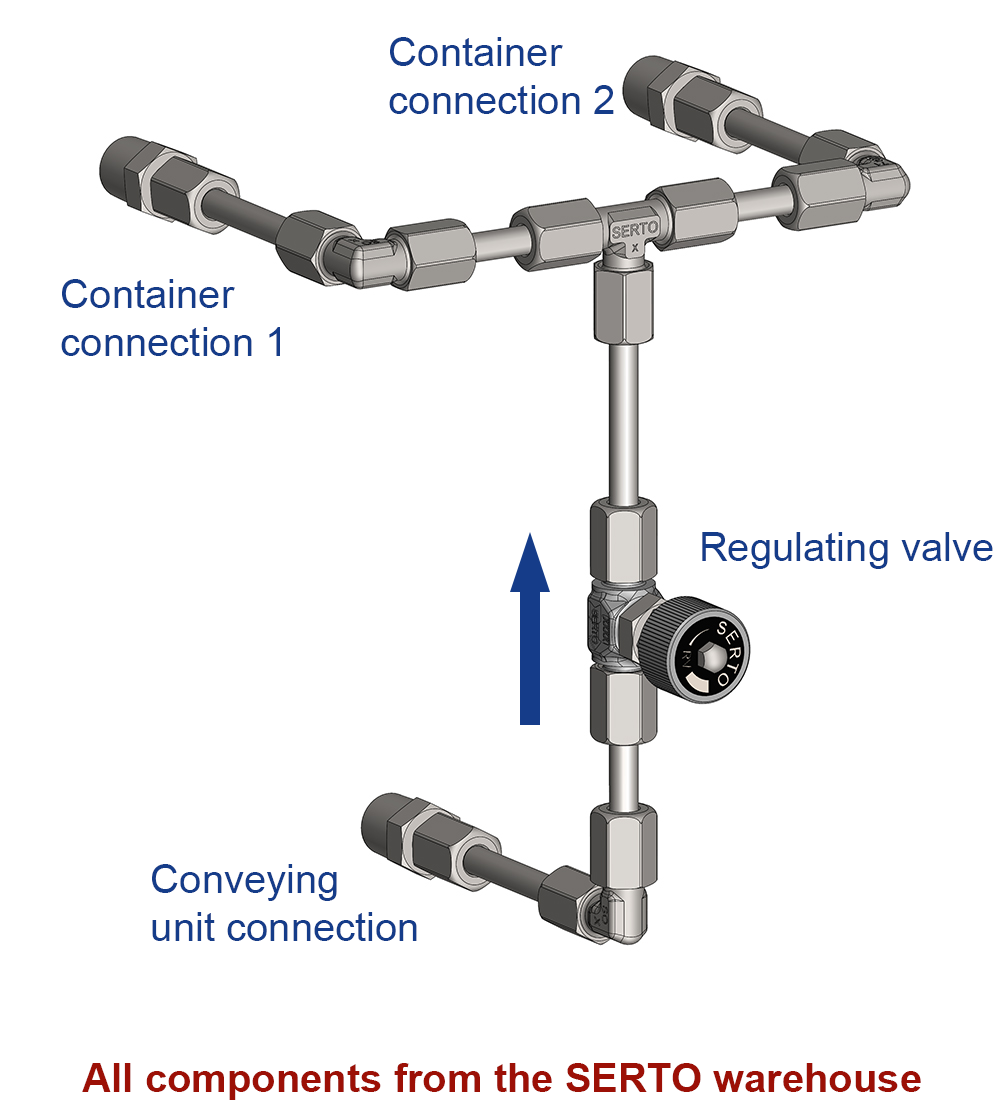

The graphics show a step-by-step system optimisation using a customer example. Costs, assembly time, the number of sealing points and the number of items to be processed changed in the course of the project to suit the customer.

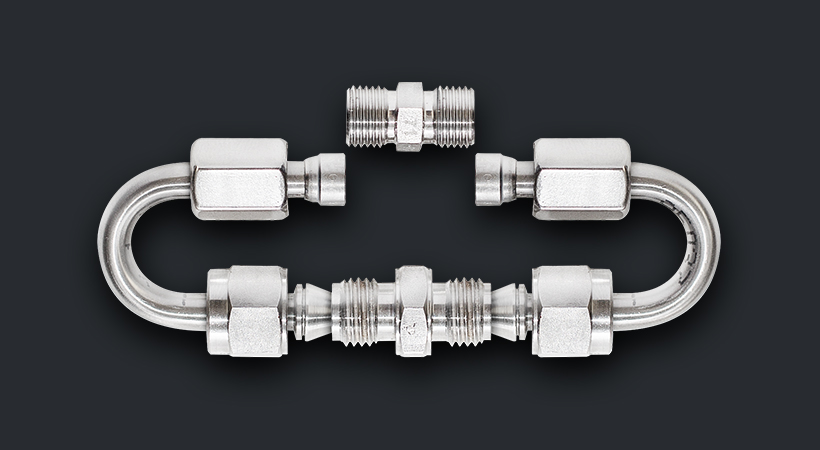

Step 1

Initial situation: Distribution of a fluid from a conveyor unit to two containers. There is a regulating valve at the centre of this. The connection points and the valve are provided. And the desire to implement this solution with SERTO products.

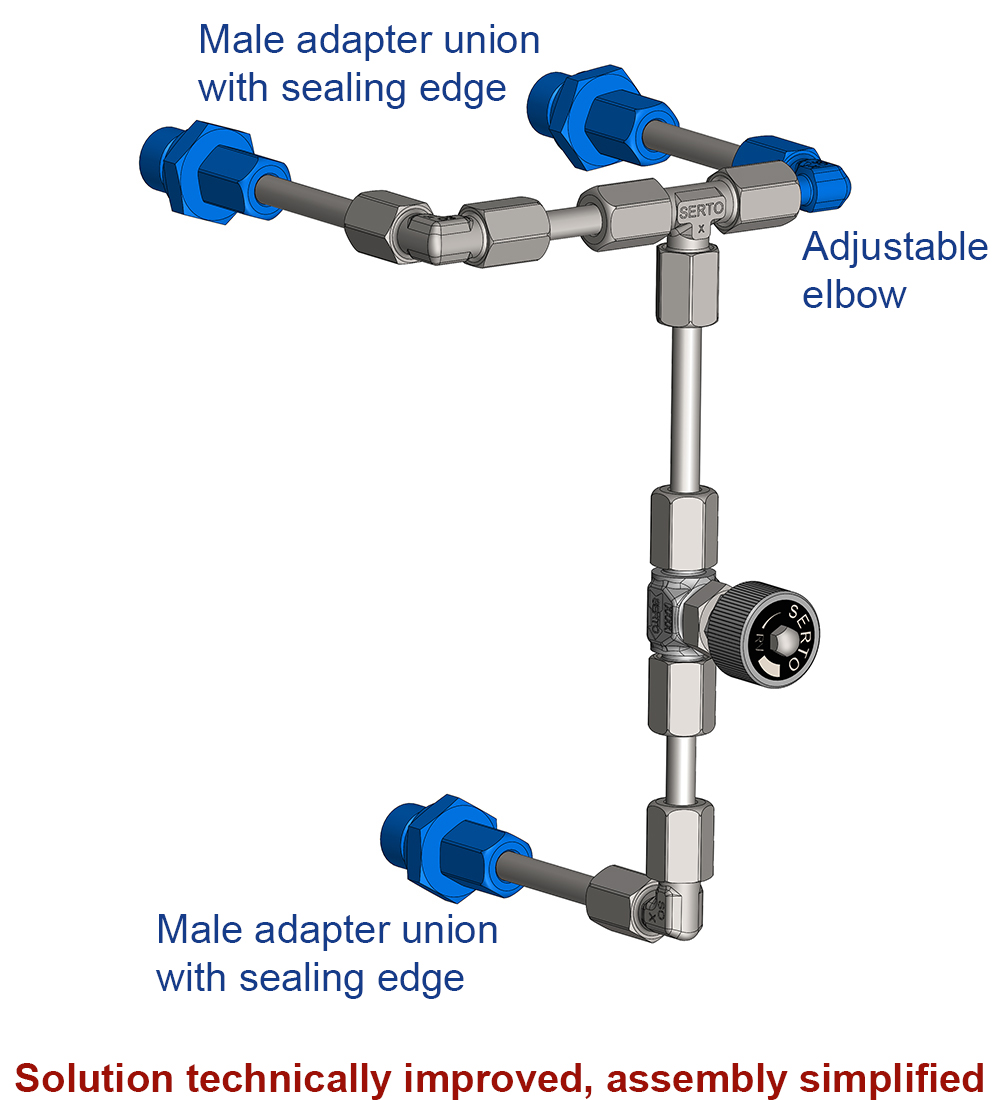

Step 2

In order to guarantee the sealing of male connectors and a uniform screw-in height of the assembly, even after repeat assemblies, we have exchanged the conical male elbow connectors with cylindrical male elbow connectors with sealing edges

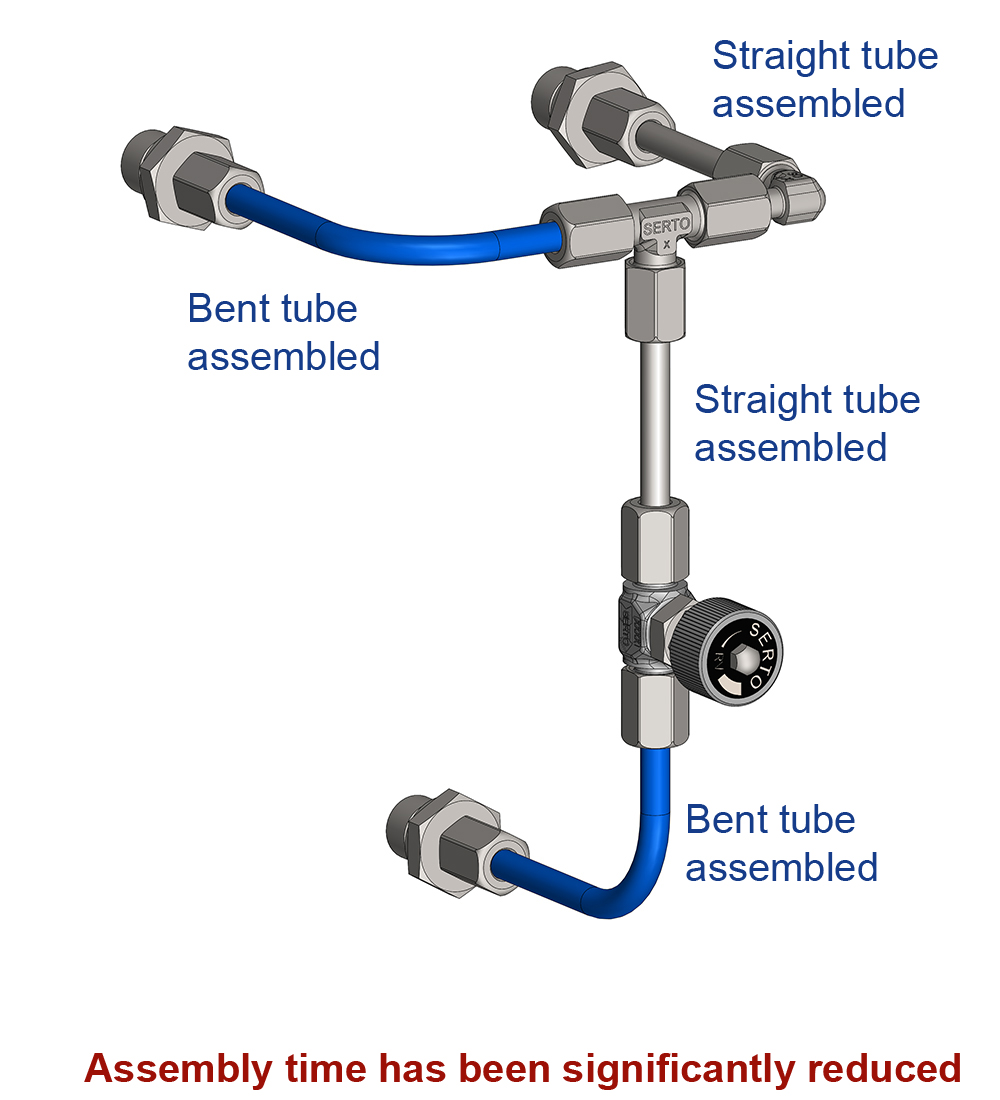

Step 3

Elbow fittings are replaced by bent tubes. This significantly reduces the number of sealing points.

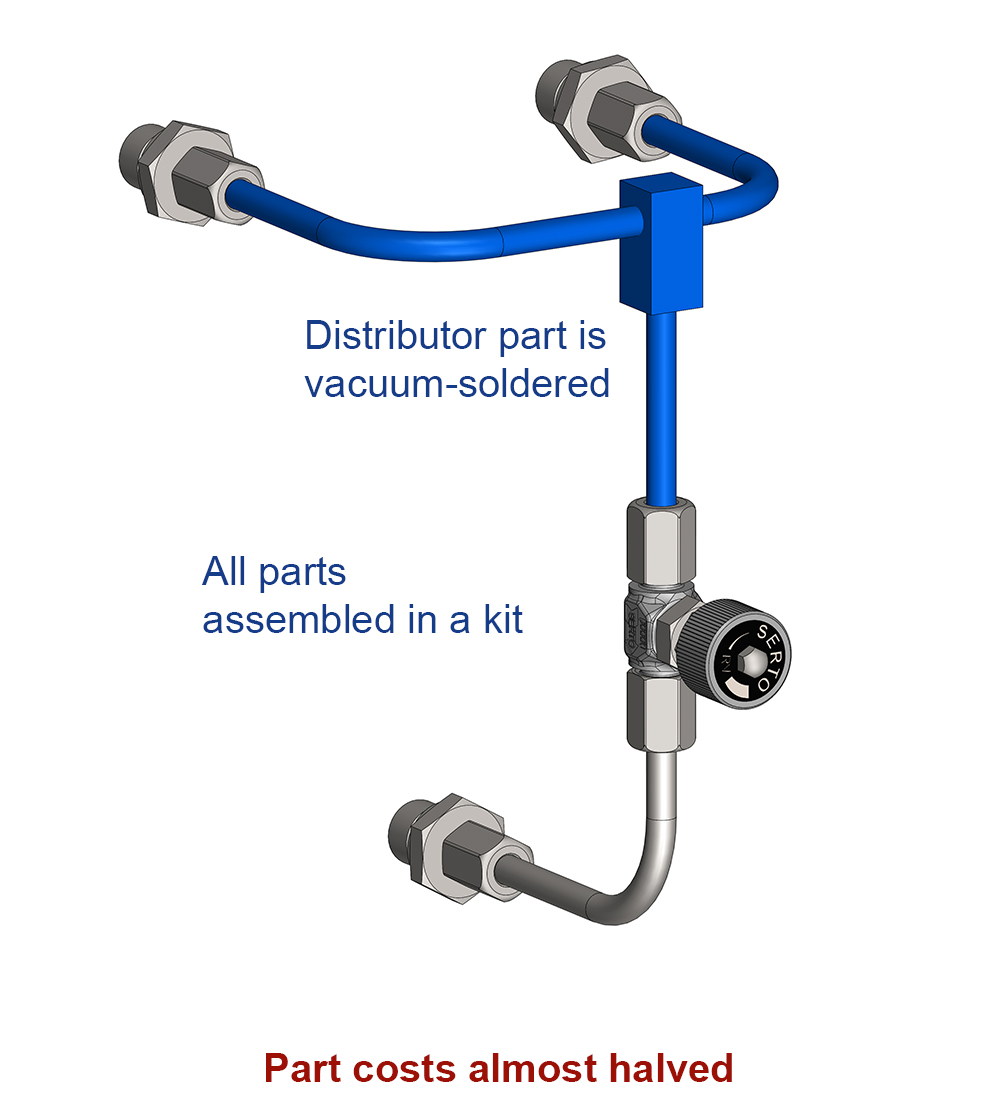

Step 4

The final solution uses a solder assembly that also eliminates the central T union. The customer receives this assembly ready for installation.