Industries

Your product and development partner

SERTO stands for flexible solutions for all industries in which media has to be transported, cooled, heated or regulated. Whether for mechanical and plant engineering, air-conditioning technology, chemicals or the food industry – SERTO components and systems are versatile, offer a high level of safety and are economically attractive.

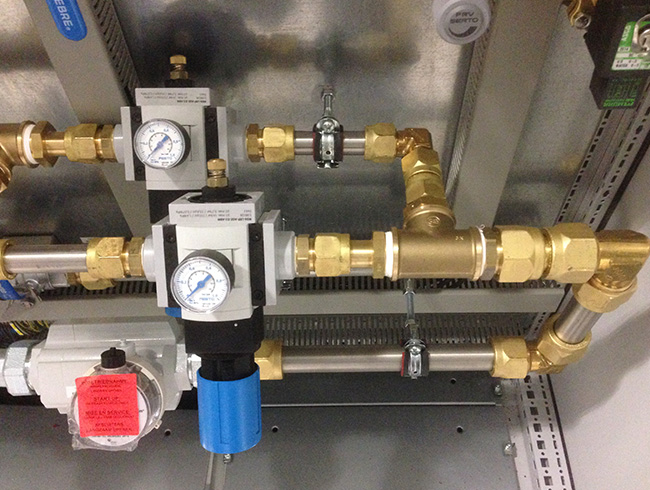

SERTO components are used to connect pipes metallically tight – no matter what material they’re made of. Regardless of the temperatures and media used, SERTO unions achieve extremely low leakage rates. They do not use soft gaskets, which can harden or show signs of settling. This is a particular advantage over longer periods and when used at extreme temperatures.

The unions and additional parts can be variably combined with each other, as in a modular system, for your very own individual solution. All metal unions have an internal stop. Thanks to this tightening limitation, a secure assembly is guaranteed.

Whether weight, resistance, pressure, temperature or approvals – whatever your requirement, we are sure to have the right solution for your application.

Case stories from customers in the various industries

Cryo-Tech

“SERTO unions offer significantly faster and easier installation due to their metallic flat-sealing system. The unions are reliably tight, even at extremely low temperatures. The quality of the parts is very high.”

GE Sensing Ltd.

“I would not hesitate to use SERTO products for future applications. Due to the compact design of the unions, a lot of space could be saved in the construction. SERTO has recommended not to disassemble the products more than 50 times in order to reassemble them. We have doubled this number and the unions are still tight.”

HM Maschinen- und Anlagenservice GmbH

“The radial system of SERTO unions allows a compact electrical cabinet design that is easily accessible for servicing. Even with the required large diameters of up to 35 mm per pipe.”

Discover the wide range of our products and the variety of our materials

Our tube union components have specific properties for every industry. We also provide additional services.- Various materials, plastics and metals

- Sizes in the standard range from 2 to 35 mm

- Modular system: SERTO components can be connected to each other like in a modular system kit

- Custom products

- Assemblies and kits

Product Highlights

Approvals and confirmations

- DVGW and SVGW gas approvals

- Lloyd’s Register

- EU REACH chemicals regulation

- Pressure Equipment Directive and CE marking (2014/68/EU)

- POPs Regulation (850/2004/EC)

- California Proposition 65 (CP 65)

- TSE/BSE in accordance with EMA/410/01

Services

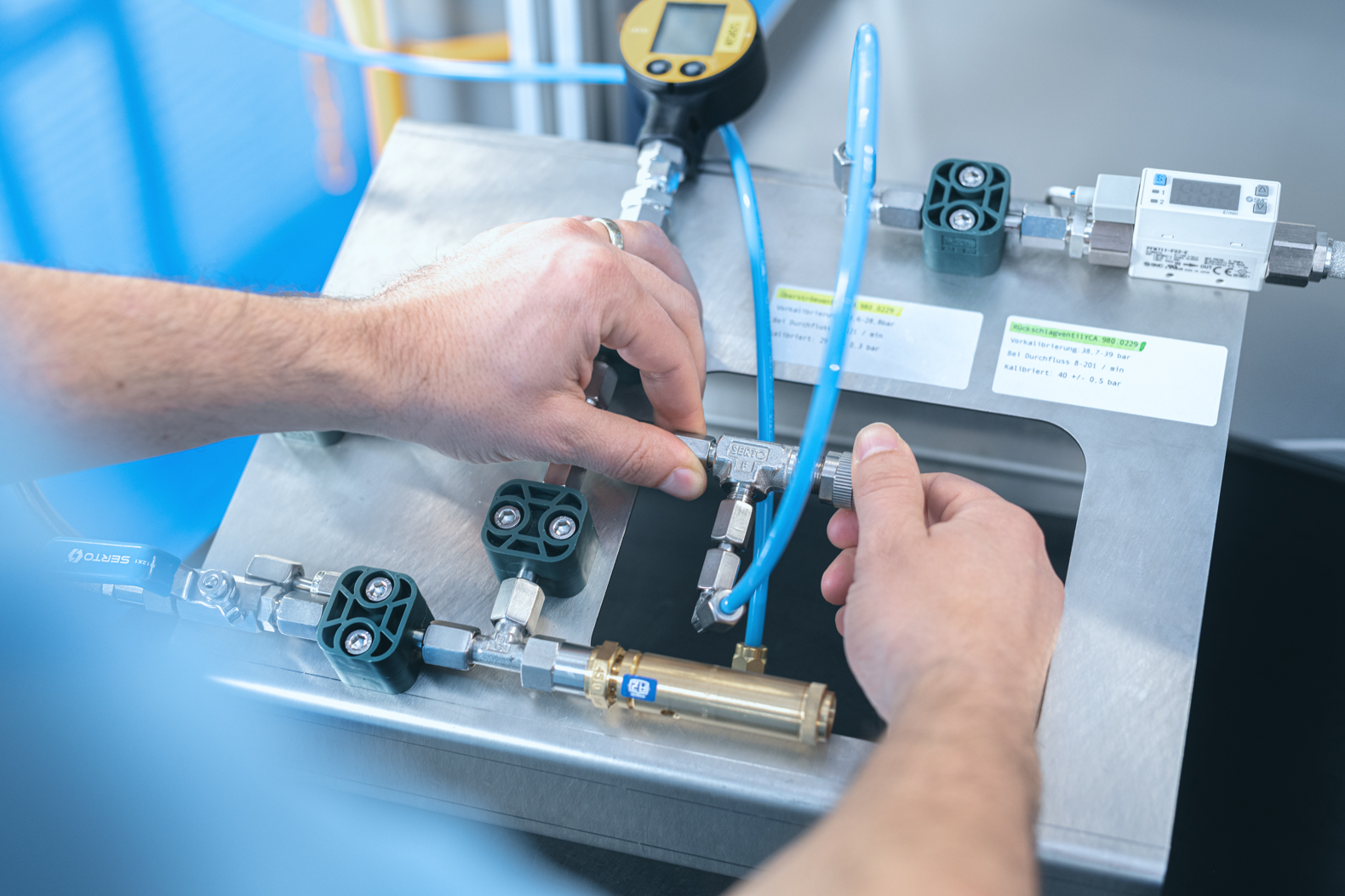

Ready-to-install assemblies

We build for you and provide full service for everything related to your assembly. Professional installation for the safety of your system is guaranteed.We also take care of the planning, production and entire distribution for you.

System solutions

Ready-to-install tubelines and kits

We produce over 150,000 metres of metal tubes – every single year! We bend and press the majority of these with unions, valves, ball valves or couplings from the SERTO range.

We also provide...

- Batch traceability: 3.1 certificates

- Tube bending, welding and cleaning

- Orbital welding

- Customised testing equipment (helium leakage test, bending fatigue strength, flow, vibration, burst pressure, climate and much more)

Industry expertise

You can rely on our product and material skills!

Our experts can provide targeted support ...

- with comprehensive expertise in design and technology

- in selecting suitable products, materials and processing steps with individual logistics concepts

- in managing and coordinating your system project, from the initial idea through to series production