Transportation

Your product and development partner

The performance of state-of-the-art vehicles, trains and ships is constantly being improved. The resolution of the conflict between sustainability and economic efficiency is also the focus in transport technology.

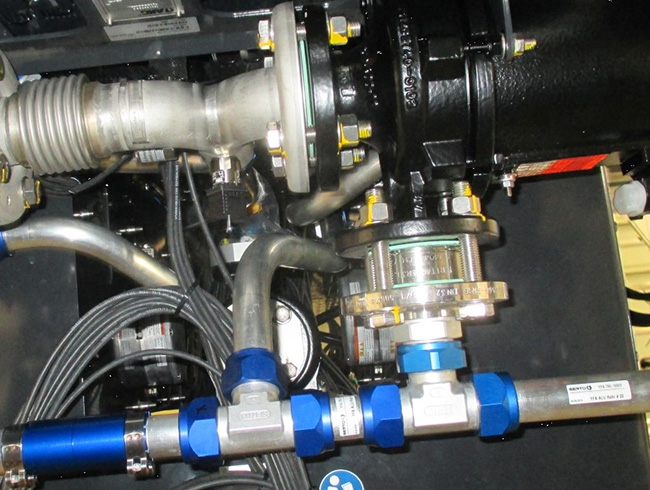

We provide smart products and technologies for the all applications in the transportation sector. SERTO components and systems can be found in sanitary units, pneumatic lines, brake lines, lubrication, dosing or process lines, and in battery cooling systems. Many years of experience in system design and optimisation coupled with custom logistics concepts and ready-to-install kits make SERTO your perfect product and development partner.

Case stories from customers in the transportation industry

Stadler Rail AG

“By using aluminium tubes with SERTO aluminium unions instead of the stainless steel solution, we were able to reduce the total weight of the replaced casing section by 63%.”

Max Bögl Bauservice GmbH & Co. KG

“SERTO provided us with exemplary support from the planning phase to the installation of the components on site. The aluminium unions are of incredibly high quality and using the special solutions, we succeeded in building up the entire cooling circuit efficiently, stress-free and tight, right from the start. By using aluminium unions and tubes from SERTO, the transport capacity could be increased by one person. Good suppliers help us to succeed with our products.”

Discover the wide range of our products and the variety of our materials

- Aluminium for weight savings

- Ready-to-install kits

- Individual logistics concepts, e.g. with delivery plans

Product Highlights

Industry-specific approvals and confirmations

- IRIS certification

- ECE R67

- American Bureau of Shipping (ABS) approval

- CL1 certification

Services

System solutions

Ready-to-install tubes and kits

We produce over 150,000 metres of metal tubes – every single year! We bend and press the majority of these with unions, valves, ball valves or couplings from the SERTO range.

Bending tubes

When it comes to bending tubes, SERTO has fully automatic, CNC-controlled bending machines that are optimally equipped for diameter ranges of up to 60 mm and an operating radius of six metres.

We also provide...

- Electronic ordering process

- Individual logistics solutions: Kanban systems, delivery plans

- Batch traceability: 3.1 certificates

- Customised testing equipment (helium leakage test, bending fatigue strength, flow, vibration, burst pressure, climate and much more)

Industry expertise

You can rely on our product and material skills!

Our experts can provide targeted support ...

- with comprehensive expertise in design and technology

- in selecting suitable products, materials and processing steps

with individual logistics concepts - in developing tailored systems and kits that meet your requirements