Production and additional services

You benefit from individual solutions and services

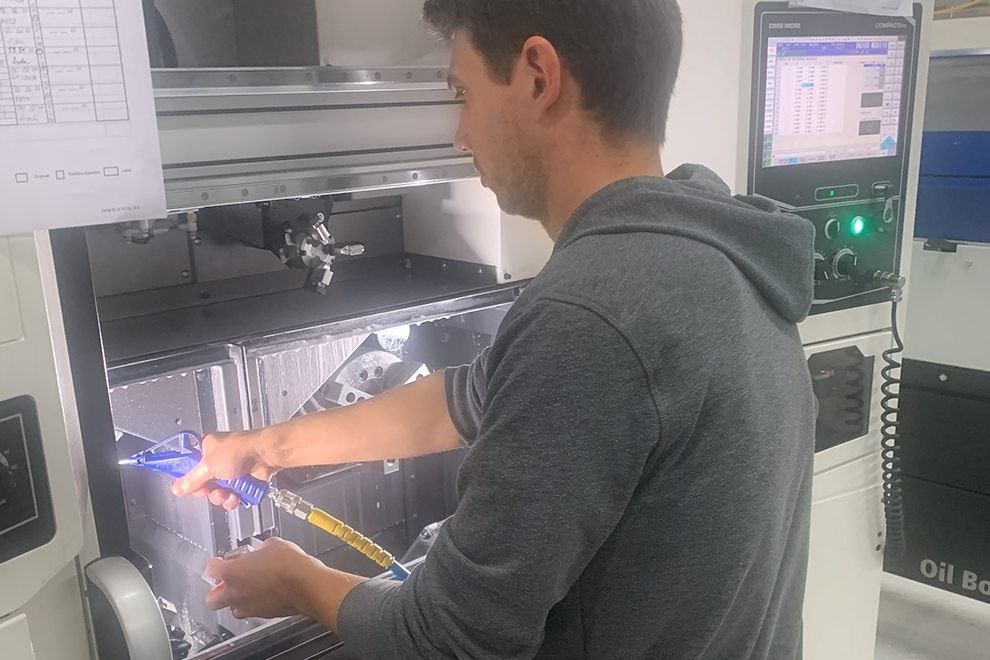

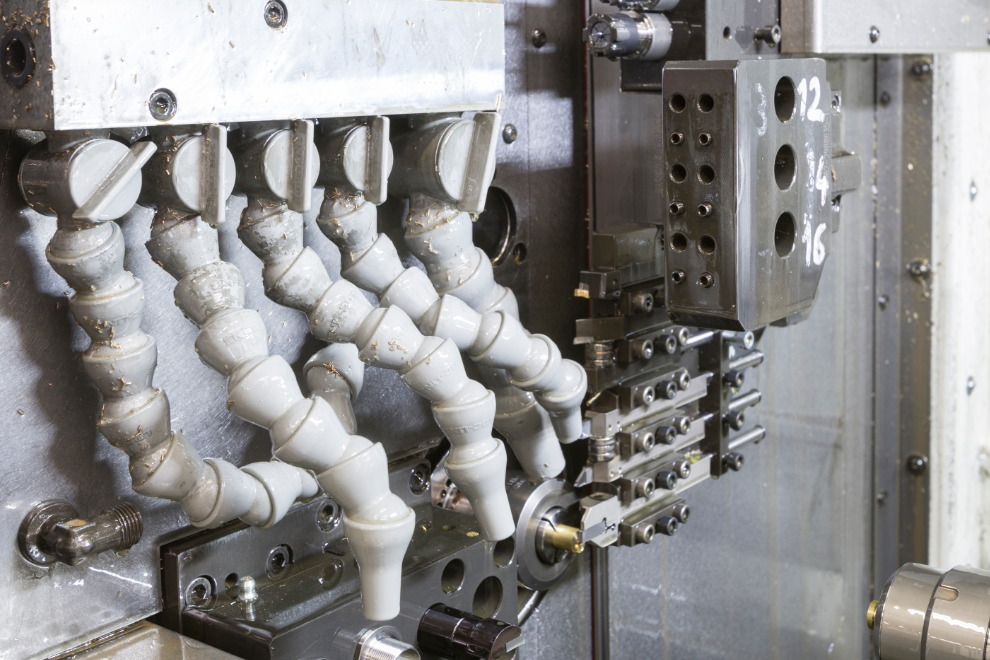

Our production sites in Frauenfeld (Switzerland), Klatovy (Czech Republic) and Brembate (Italy) boast state-of-the-art, highly efficient machinery, which we continuously update. Whether dealing with unions, couplings, valves, tubes or hoses, we are your producer for tube union components.

We also bend tubes, assemble tubelines and deliver ready-to-install assemblies. Our clean room is an impressive addition to our extensive range of services.

Benefit from our many years of expertise in dealing with demanding materials, complex geometries and high-quality surfaces.

Production in figures

Each year, our 140 production employees produce...

- 6 million stainless steel turned parts

- 1 million stainless steel shaped parts (angle, T and cross pieces, and valve bodies) from forged blanks

- 220 km seamless stainless steel pipes

- 700 km hoses

Machines at work

Our fleet of machinery

- 42 CNC turning centres

- 2 CNC milling machines

- 4 six-spindle machines

- 5 bending machines

- 2 measuring cells (optical pipe measurement)

- 3 sawing machines

- 3 handsaws

- 5 tube bearing towers

- 2 drills

Additional services for the highest quality

- Orbital welding

- Welding (Certification to levels CL 1 and CL 2 in accordance with DIN EN 15085 for the railway industry)

- Vacuum soldering

- Parts testing (up to 100% with record)

CNC bending centre

Assemblies

Ready-to-install tube lines

We produce over 150,000 metres of metal tubes – every single year! We bend and press the majority of these with unions, valves, ball valves or couplings from the SERTO range for customer-specific solutions.

Particularly for the railway and shipbuilding sectors, where cutting ring unions up to size 42 are used, we can also use EXMAR DIN unions as an alternative or in addition to the SERTO range. Benefit from short response times and fast, flexible service thanks to the large stock available in Frauenfeld.

The clean room

Unions or valves made of stainless steel, brass or plastic that are used in applications where surfaces in contact with media are subject to high cleanliness requirements – such as in the semiconductor industry or in medical technology – are cleaned in the cleaning plant and packaged in the clean room.

The cleaning plant consists of different baths. An air curtain prevents the cleaned components from being contaminated by dirt from the air. Quality is monitored in line with ASTM (American Society for Testing and Materials) standards and each cleaning order is documented.

The cleaned parts are then assembled in the ISO Class 8 clean room, individually shrink-wrapped in bags and packaged.

Cleaning options

- US: cleaned in an ultrasound bath, not lubricated

- OX: cleaned in an ultrasound bath, lubricated for oxygen systems

- SI: cleaned in an ultrasound bath and lubricated silicone-free for use in combination with paints and varnishes

The SERTO cleaning plant

- ASTM standard

- Ultrasound cleaning bath with alkali, with acid and with deionised water

- Rinsing bath with osmotic water

- Drying sections

Clean room

- ISO Class 8

- Directly adjacent to the cleaning plant

- Air-conditioned

- An annual validation of the clean room carried out by an external inspection body guarantees compliance with the prescribed particle values in the air

Logistics

Supply chains today are more complex than ever and require efficient management. You can rely on our innovative logistics concepts, which can be adapted to your company’s specific requirements.

- Kits: We package and store your kits (assembles and/or assembled tubelines) in accordance with your specifications. Just-in-time delivery and in pre-defined batch sizes

- Labelling and packaging with customer number and in accordance with your specifications

- Delivery schedules: Avoid fluctuations in material prices and benefit from optimised prices for large production quantities

- Kanban: just-in-time delivery, especially in C and B parts management

- Consignment warehouse

We are sure to have just the right solution for you.

Your Contact

Have questions about our products or services? Our experts will be happy to help.